Widely regarded as the first automobile that was affordable for middle-class Americans, the Ford Model T occupies an important place in social and technological history. It enabled inexpensive transportation on a huge scale, while its influence was felt in the pioneering principles of management used in its production.

On 26 May 1927, Ford and his son drove the 15-millionth vehicle out of the factory. It remained the most sold car in history until 1972, when it was surpassed by the Volkswagen Beetle.

Here’s the story behind the Ford Model T.

Listen Now

Listen NowThe blueprint

When the first Model T was wheeled out of Ford Piquette Avenue Plant in Detroit, Michigan on 27 September 1908, it wasn’t the first automobile on the market. Nor was it the first Ford.

Ford had founded several companies before 1903, when at age 39 he founded the Ford Motor Company. Between then and 1908, the Motor Company had produced a handful of models, but none achieved the success of the Model T. Henry Ford had conceived of the car as being reliable and easily maintained, not to mention easily manufactured, while attainable by working people.

With the Model T, Henry Ford aimed to “build a motor car for the great multitude. It will be large enough for the family, but small enough for the individual to run and care for. It will be constructed of the best materials […] But it will be so low in price that no man making a good salary will be unable to own one.”

What makes a Model T?

The Model T was principally designed by Childe Harold Wills, Joseph A. Galamb and Eugene Franks. It was a rear-wheel drive vehicle that ran on gasoline with a top speed of 42 miles per hour, owing to an inline four-cylinder engine mounted at the front that was started by a hand crank. Water pumps cooled the engines of the first 2,447 Model Ts, and its wheels were so-called artillery wheels made from wood.

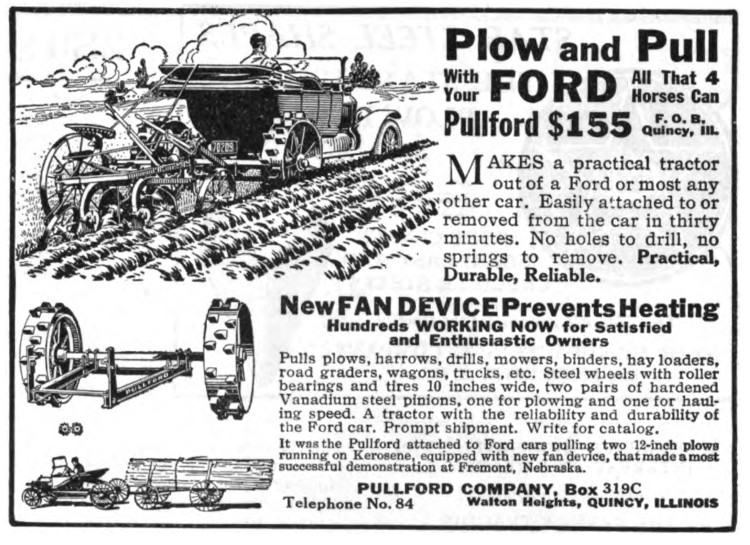

Its vanadium alloy steel construction was light but hardy, and its ground clearance made it capable of travelling off-road. This made it a versatile working vehicle, carrying an engine which could be used to drive farm equipment.

Pullford auto-to-tractor conversion advertisement, 1918.

Image Credit: Public Domain

The mass production system

By 1918, half of the cars in the United States were Model Ts. The explosion in production was possible thanks to a revolution in manufacturing at Ford’s Highland Park factory. During the early years of the Ford Motor Company, groups of two or three men made just a few cars a day. But by adopting new principles of management, Henry Ford made an early and influential stab at what became known as the mass production system.

Ford’s efforts drew on the scientific approach to management promoted by American engineer Frederick Winslow Taylor. He argued that the production process should be divided into the simplest possible tasks, performed by workers in the most effective way possible.

Ford Model T assembly line, photographed in the 1920s.

Image Credit: Science History Images / Alamy Stock Photo

At the turn of the century, Ransom E. Olds had pioneered the assembly line with which the Oldsmobile Curved Dash was developed. However, Ford’s implementation of the Taylorist principle and the moving assembly line at the Model T factory resulted in significant efficiency advances.

By producing lots of standardised products, made with standardised parts, by specialised machinery and workers at different stages of the production line, production costs were hugely reduced.

Fruits of labour

This mass production system was first introduced at Highland Park, Michigan in 1913. Almost immediately, production of the Model T rose fivefold. By 1914, production time per vehicle had shrunk from 12-and-a-half hours to 93 minutes.

This technological approach to organisation spread beyond factories to attitudes and ideals. It contributed to the notion of wage labour with regular hours and pay becoming dominant not just in the United States but in Europe and beyond, too.

Though mass production dramatically improved efficiency, it undermined the value of work by making it repetitive and less autonomous. Workers became less essential to the production process as they had to master fewer skills, and thus could be more easily replaced.

Growing market

All of Ford’s increased productive power would have been for nothing if there had not been a growing market for the Ford Model T. As it turned out, the Ford company received 15,000 orders for the car within days of its release.

Car dealers equipped with Model Ts promoted automobiling to the American public, who were attracted to what had previously been a luxury good. Cars would greatly alter the standard of living, reducing travel barriers for work and leisure. The Model T became the most popular car in the United Kingdom as well as the United States. As production increased and methods were further refined, Model Ts were sold cheaper and cheaper.

How much did a Ford Model T cost?

Initially, in 1909, a two-seater Ford Model T (the ‘Runabout’ version) would have cost around $825, which equates to nearly $25,000 in 2021. In 1910, the price increased slightly, to $900 (equivalent to just over $26,000 in 2021). With the introduction of the mass production system, though, the Model T became increasingly efficient to produce. With a reduction in manufacturing hours came a reduction in price.

The price of the Model T fell steadily over the ensuing decades, hitting a low of $260 in 1925 for a two-seater (equivalent to roughly $4,000 in 2021).

The Model T was in production until 1927, by which point larger and more luxurious cars were available. Yet by then, it had become entrenched in American folklore, nicknamed the ‘Tin Lizzie’.